Creating a Future with New Principles, Properties, and Functions

Materials science is attracting attention as a solution to challenges faced in modern society, such as global warming, energy transition, and circular economy. Materials science is an academic field fused with physics, chemistry, and material engineering, fostering significant innovations in industries and societies.

In 1999, the Graduate School of Frontier Sciences (GSFS) established the Department of Advanced Materials Science in the Division of Transdisciplinary Sciences. The department is now one of the largest global transdisciplinary research hubs of materials science, promoting research in association with the Institute of Physical and Chemical Research (RIKEN), National Institute for Materials Science (NIMS), National Institute of Advanced Industrial Science and Technology (AIST), and Super Photon Ring-8 GeV (SPring-8), a giant synchrotron radiation facility.

We present an overview of the world of materials science, exploring the cutting-edge research conducted at the Department of Advanced Materials Science at the GSFS to unlock the dynamic potential of this discipline.

First, what is materials science?

Materials science is an interdisciplinary academic field that is based on physics, chemistry, and material engineering. Humans have attempted to comprehend materials, and they have hypothesized and repeatedly experimented on materials since Ancient Greece era. However, it was not until the 20th century that it became possible to understand materials from a unified scientific perspective. The knowledge of materials science has rapidly accumulated over the past century and has driven industrial and societal innovations.

A prominent example of such innovations is semiconductors, which form the foundation of modern electronics. The microfabrication processing on silicon wafers has significantly increased the number of transistors in an integrated circuit (IC)—commonly referred to as Moore’s law. However, transistor miniaturization is now reaching its physical limit. Thus, next-generation materials should be developed to replace silicon to achieve the various functions demanded for modern semiconductor devices.

Another example of the aforementioned innovations is the superconductivity harnessed in the Linear Chuo Shinkansen. It is a phenomenon that occurs when electrical resistance becomes zero at an extremely low temperature in certain materials, such as metals. Applications based on superconductivity began to hold promise only after superconductivity at a relatively high temperature (although it was as high as −195°C) was discovered in 1986. Scientists are currently working to comprehend the principles of superconductivity, practicalize it widely, and achieve superconductivity at room temperature.

Humans are surrounded by cutting-edge devices, such as smartphones, liquid crystal displays, and solar power generators. These devices were developed solely because of the discoveries of new materials.

Increasing Expectations for Materials Science

Materials are fundamentally combinations of chemical elements (118 elements exist); therefore, the number of possible combinations is infinite. Thus, materials will continue to be discovered or manufactured. Even in known materials, new principles, properties, and functions can frequently be discovered by changing conditions, such as temperature, pressure, magnetic field, or additives.

In addition, contributions to carbon neutrality and the prevention of marine pollution by controlling decomposition processes or providing additional properties for recycling have been recently required. Based on the prediction of these needs, the Japanese government advocated the “Element Strategy Initiative” in 2004, the first of its kind globally, and has been promoting research on materials science. “Materials” is one of the basic technology initiative themes in the ongoing “Integrated Innovation Strategy 2024” *1, leading to the initiation of successive large-scale research projects.

The Uniqueness of Materials Science is its High Degree of Freedom

Koji Kita, a professor and head of the Department of Advanced Materials Science, talked to Sosei about materials science as follows.

“An atom comprises an atomic nucleus and multiple electrons. Materials are super many-body systems comprising 1023 nanoscale elements *2, which amounts to an astronomical number of atoms. Furthermore, the degree of freedom humans possess in using materials is just a part of the astronomical degrees of freedom that super many-body systems possess,” says Kita.

This high degree of freedom is what makes materials science unique; thus, the scope of materials science research is extensive. To address the needs of industry and society, a “backcasting” approach has been increasingly adopted along with conventional approaches that explore the unknown mechanisms and properties of materials. Other approaches exist. These varied approaches and the degree of freedom elevate the potential and expectations of materials science.

NOTES

-

Integrated Innovation Strategy 2024 is the fourth annual strategy outlined as the 6th Science, Technology, and Innovation Basic Plan.

The key focus areas include materials, artificial intelligence technology, and biotechnology. - In the International System of Units (SI), “mol” is the unit of the amount of a substance. One mol is defined as 6.02 × 10^23 (Avogadro’s constant) atoms or molecules.

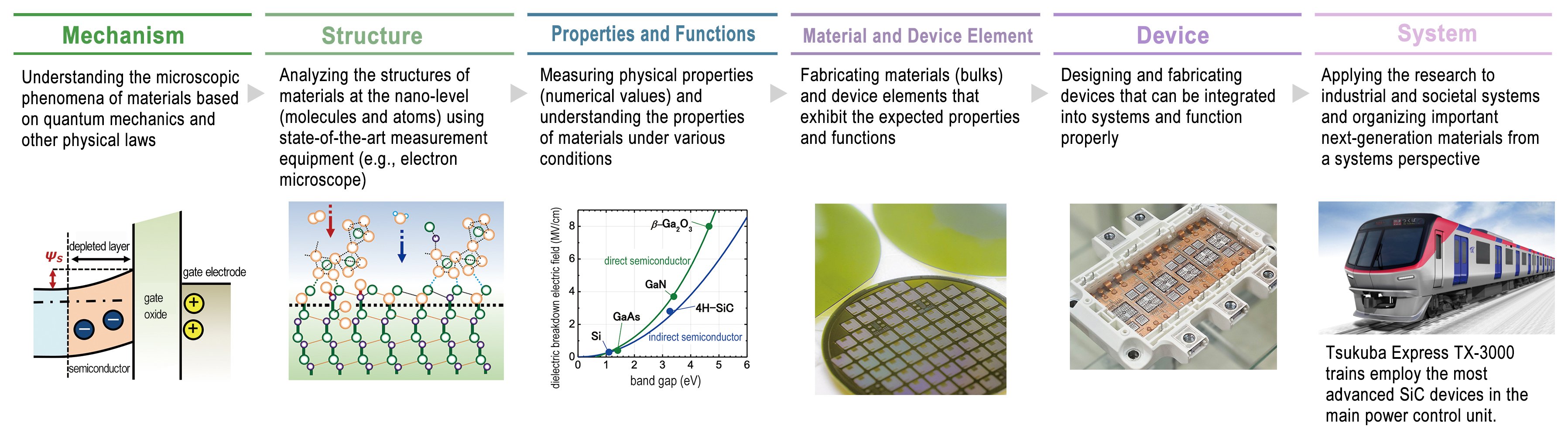

Research Scope of Materials Science

(Example of Power Superconductivity)

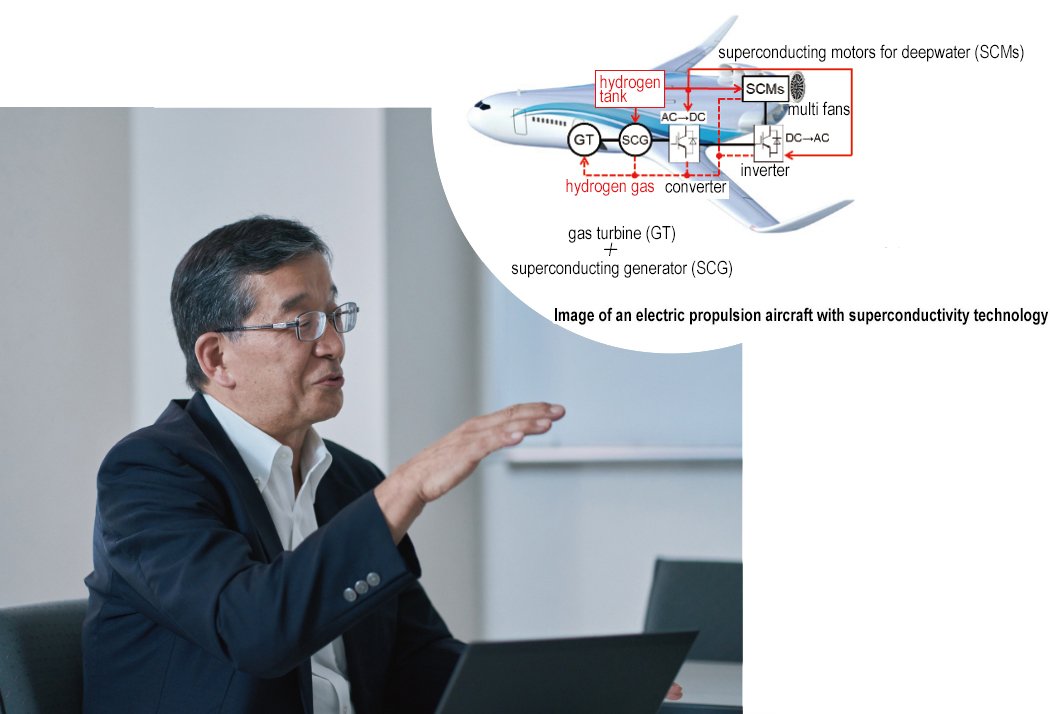

[1] Developing Electric Propulsion Aircraft

Interview with Hiroyuki Ohsaki, Professor, Department of Advanced Energy

Hiroyuki Ohsaki researches electric energy equipment and systems that utilize advanced materials, such as superconductivity. His work spans various areas, including electric power, transportation and space fields.

“One of the research themes I am currently focused on is the development of superconducting motors to equip electric propulsion aircraft with. This involves developing design methods, analyzing the properties of the motors, developing measurement methods of the specific energy-loss properties of superconductivity, and evaluating the loss properties,” says Ohsaki.

He emphasizes that the excellent properties of superconducting wires are crucial for the development of smaller and lighter superconducting motors. In addition, it is important to improve the performance of the power converter and device for driving such motors.

Ohsaki states that there is no doubt that the excellent properties of superconductor and power device materials will significantly impact the development of smaller, lighter, and more efficient propulsion systems, thereby anticipating wide range of practical applications for new materials.

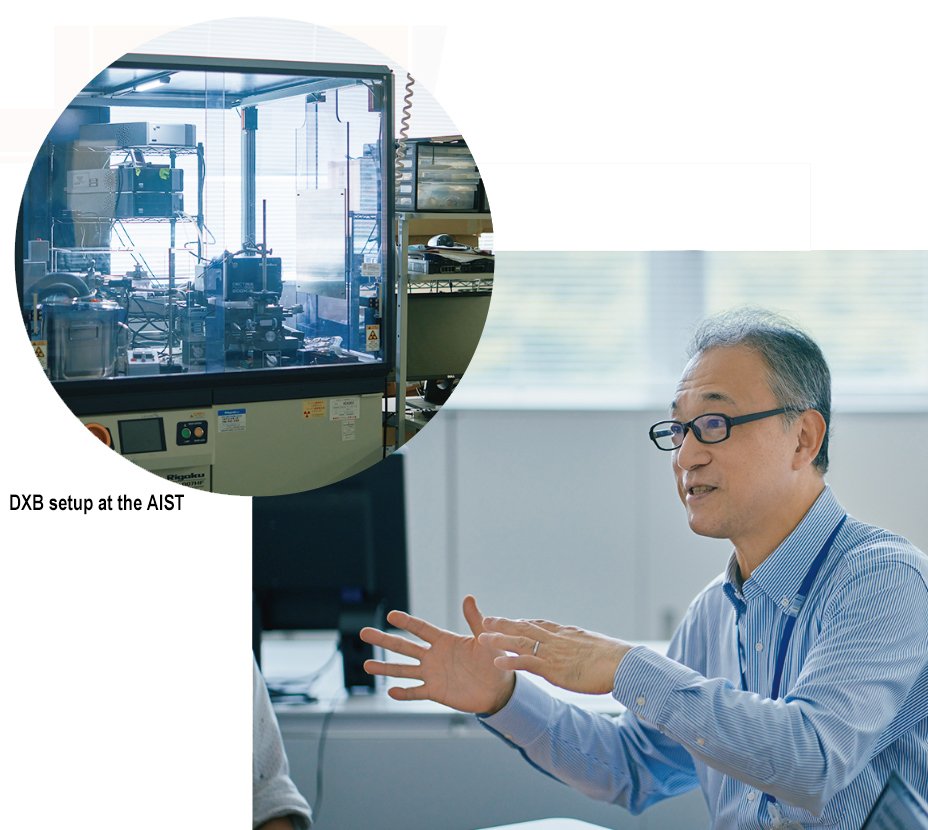

[2] Importance of Measurements in Materials Science

Interview with Yuji Sasaki, Professor, Department of Advanced Materials Science

(Supervisor of the cover story)

Yuji Sasaki is an expert in measurement science. He develops methods for measuring the movement of individual molecules in less than a millisecond using X-rays and electron beams.

“I developed the Diffracted X-ray Tracking method using beamlines of the SPring-8 accelerator 20 years ago. It was a method of labeling a targeted single molecule with gold nanocrystals, which appeared unrealistic at the time; however, it was successful. Afterward, I developed the Diffracted X-ray Blinking (DXB) method using a laboratory-size X-ray device, and I still use this method all the time in the joint research project with the AIST,” says Sasaki.

In materials science, scientists conduct research using various measurement equipment and methods. Advancements in measurement technology support materials science.

Forefront of Materials Science at the GSFS

The Department of Advanced Materials Science has 32 laboratories engaged in various research fields, such as quantum phenomena, novel materials exploration, organic electronics, and heat-resistant materials. Six of them are introduced herein as follows.

- 1. A New Mechanism of an Element Important for Quantum Computers

- 2. Start the Future of Spin Caloritronics by Double Approaches

- 3. The World’s Discovery of a High Polymer Gel That Toughens Instead of Cutting When Extended

- 4. Aiming for the High Performance of Power Devices from the Study of Interface in Nanoscale

- 5. The Goal of Modern Alchemy is Hyper-Super Heat-Resistant Material Design

- 6. Project Management for Solving Social Problems by Materials Science

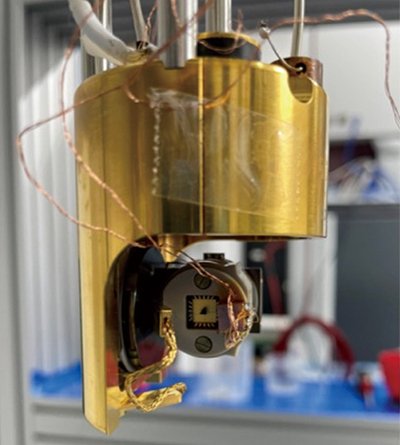

1. A New Mechanism of an Element Important for Quantum Computers

Interview with Takasada Shibauchi, Professor, Department of Advanced Materials Science

Takasada Shibauchi and his laboratory members research “the quantum phase of matter” (the phase where many electrons in materials display by the “quantum many-body effect”) by efficiently using cutting-edge experimental technology to measure physical properties at low temperatures. In quantum many-body effect, many microparticles (quanta) regulated by the laws of quantum mechanics gather in a system interacting with each other. Electrons, a type of quantum, exhibit quantum-level properties, including charge, orbital, and spin*1 degrees of freedom. Thus, the development of next-generation materials using these properties is anticipated.

The latest significant news from the research of Shibauchi’s group is proof of a new mechanism that can be a basic unit of quantum information (quantum bits or qubits) in quantum computers*2. Although methods, including superconducting circuits, photons, and ions are advocated, challenges are still encountered in the realization of quantum bits. The most probable wild card with excellent intense resistance to environmental noise is “topological quantum computation.”*3

“Topological quantum computation requires a theoretical particle called the Majorana particles*4. Scientists worldwide seek such particles; however, their existence remains unproven. We attempted to solve this problem through experiments based on the theoretical model called the Kitaev spin liquid*5 by cooling ruthenium chloride (α-RuCl3), a kind of magnetic topological insulator with a honeycomb planar structure, to an extremely low temperature and applying a magnetic field to it. Thus, we successfully confirmed that the property—the changes in specific heat by changes in the magnetic field direction—was the same as that exhibited by the Majorana particles (quasiparticles) when they were created in a sample,” explains Shibauchi.

Nevertheless, this is just the first step to realizing topological quantum computing. For the next step, a quantum operation by the Majorana quasiparticle swap is required; however, electricity cannot flow in ruthenium chloride because it is a magnetic insulator. Thus, Shibauchi is considering a method using a magnetic field gradient, which will be groundbreaking if achieved.

NOTES

- Similar to the magnetism of magnets (north and south poles), elementary particles, including electrons, exhibit magnetism called spins.

- While conventional computing uses a bit with electrical ON/OFF that corresponds to binary 1/0, quantum computing uses quantum mechanical phenomena (superposition with zero and one) as a bit (qubit) to facilitate superparallel computing.

- However, in a 2D space, a particle may occupy a different state (topology) from the original one after such a swapping. This “non-abelian anyon” is used as a qubit in the topological quantum computation method.

- “Non-abelian anyon” comprises of the theoretical Majorana particles, in which a particle and an antiparticle exhibit the same properties. In the meantime, when the change in material state can be regarded as the addition of a virtual particle, it is called a “quasiparticle.” The discovery can be the first important clue to applying the “Majorana quasiparticles” as qubits.

- It is quantum spin in a liquid state based on the Kitaev model suggested by Alexei Kitaev in 2006. It is considered that the Majorana quasiparticles can exist in the Kitaev spin liquid, and the discovery by Shibauchi’s group demonstrated it.

This is a measurement instrument with double-rotating axes. Shibauchi’s group used it to measure the specific heat by applying a strong magnetic field to ruthenium chloride at an extremely low temperature.

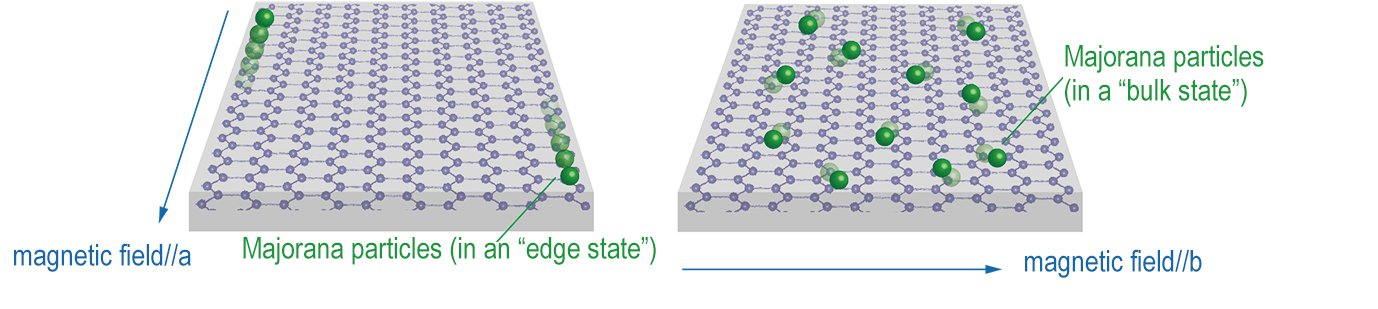

By changing the direction of the magnetic field, two states of the Majorana quasiparticles were observed in ruthenium chloride. The image on the left shows the Majorana particles in an “edge state,” flowing on the edge of a sample. The image on the right shows the Majorana particles excited in a sample in the “bulk state.”

2. Start the Future of Spin Caloritronics by Double Approaches

Interview with Ken-ichi Uchida, Professor, and Yusuke Nakanishi, Associate Professor, Department of Advanced Materials Science

Ken-ichi Uchida has been consistently engaged in research on “spin caloritronics.” Spin caloritronics is a term coined from spin (magnetism), calorie (heat), and electronics. Uchida is the one who paved the way for the spin caloritronics field.

The beginning of his research on spin caloritronics was his graduation paper for Keio University, in which he reported an observation of the “spin Seebeck effect,” for the first time in the world. (Spin Seebeck effect: a temperature difference applied to the two edges of a magnetic material generates spin currents and converts them into electric currents). As a graduate student at Tohoku University and subsequently working at the NIMS, he demonstrated the mechanism of spin caloritronics and pioneered its elemental functions.

Uchida began working at the GSFS in April 2024. In addition, he leads the “Japan Science and Technology (JST) Strategic Basic Research Program, Exploratory Research for Advanced Technology (ERATO) Uchida Magnetic Thermal Management Materials,” *1 serving as the Distinguished Group Leader of the Research Center for Magnetic and Spintronic Materials, NIMS, on a cross-appointment.

“Magnets used for motors and generators possess hidden functions and abilities. For example, if a magnet can directly convert heat into electricity, refrigerate objects by adding electric currents or magnetic fields, or autonomously control heat flow, this could be an innovative technology for saving and generating energy. In a bid to apply these ideas, we named the energy materials “magnetic thermal management materials.” We are attempting to produce three types of materials: thermoelectric permanent magnets (for converting heat into electricity), magnetic hybrid thermal switching materials (for heat control), and phase-interface-controlled magnetic refrigeration materials (for conducting heat),” says Uchida.

What is remarkable about his research is that not only did he scaleup spin caloritronics from the nano-level (mechanism demonstration and elemental function cultivation) to the macro-level (producing “bulks”) and is working to facilitate its practical application.

“It is no use replicating the research conducted by my research group in the NIMS here at the GSFS,” says Uchida. He is conceiving a project idea with a different theme to conduct with Nakanishi, who recently joined Uchida’s laboratory from Tokyo Metropolitan University. Nakanishi is an expert in nanomaterials science, working on the invention and evaluation of nanomaterials and precision structure control in low-dimensional nanospace.

While the approach in the NIMS is to proceed from nano to macro, the approach at the GSFS is to delve into nano. Spin caloritronics is promising.

NOTES

- ERATO is one of the Strategic Basic Research Programs promoted by the Japan Science and Technology Agency (JST). The JST selects project directors with outstanding abilities and forward-thinking ideas. All the projects are named after the directors. Uchida’s project began in October 2022 and will continue through March 2028, spanning five and a half years.

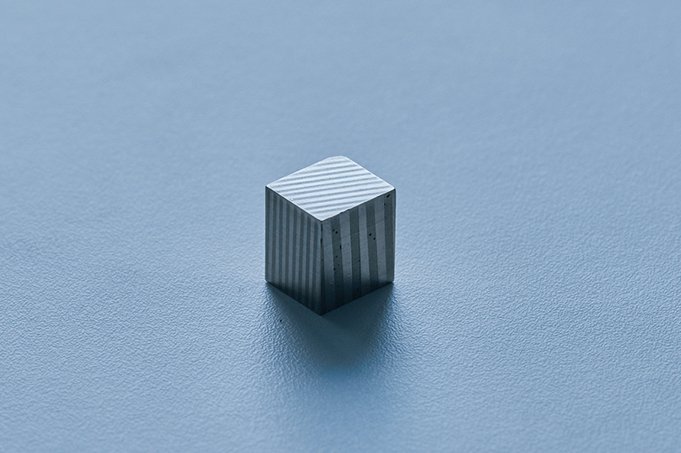

This is a thermoelectric permanent magnet (artificially tilted multilayered magnet) developed by Uchida in the NIMS. When an electric current is applied, this magnet can refrigerate itself on one side with the heat flow that goes in the direction intersecting the electric current. In addition, it can generate electricity by exploiting a heat difference.

3. The World’s Discovery of a High Polymer Gel That Toughens Instead of Cutting When Extendeds

Interview with Koichi Mayumi, Associate Professor, the Institute for Solid State Physics/Department of Advanced Materials Science

Natural and artificial long and large molecules that form chains are called polymers. They can be found in natural and synthetic fibers or plastic and even in the proteins and DNA of organisms. Multiple polymers that bond (cross-linking) sporadically, forming 3D networks and containing solvents, such as water, are called gels. Gel products are familiar in daily life: konjac, jelly, diapers, and soft contact lenses.

Polymeric materials, including gels, are generally soft and can be easily deformed or broken with relatively small force. However, the toughness of gels has rapidly improved recently, and tough gels have been investigated for applications in medical materials, soft actuators, etc.

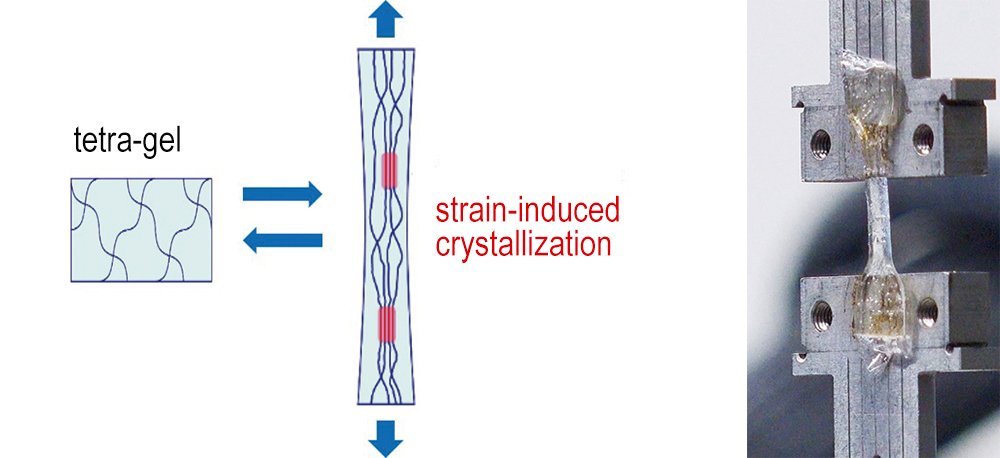

Koichi Mayumi develops polymer gels that “toughen” instead of “breaking” when extended. In 2021, he discovered that a specific type of polymer gel (slide-ring gel*1) can tolerate high strain by forming bundles with stretched chains and crystallizing themselves (strain-induced crystallization.) Consecutively in 2022, he observed that strain-induced crystallization occurs in another type of gel. Furthermore, in February 2024, he discovered that strain-induced crystallization occurs also in tetra-gel, which is the most common type of gel.

“I am currently working to achieve “strain-induced crystallization” in more gel types. Two essential conditions are required to achieve this. The first is uniformly linked networks, which make polymer chains align in the same direction when extended (uniform orientation). The second condition is that extended polymer chains form bundles. The key to achieving this is the density of the polymer chains. Strain-induced crystallization occurs when the orientations of polymer chains are uniform, and their density exceeds a certain level,” explains Mayumi.

Polymer gels are beginning to exhibit new potential with strain-induced crystallization.

NOTES

- In 2001, Professor Kozo Ito in the Department of Advanced Materials developed the slide-ring gel. The slide-ring gel is a polymer gel comprising polymer chains linked with cyclic molecules. When the gel is deformed, the cyclic molecules slide to uniformly orient the polymer chains.

(Left) Image of reversible strain-induced crystallization in a tetra-gel.

(Right) Experiment of extending polymer gels.

4. Aiming for the High Performance of Power Devices from the Study of Interface in Nanoscale

Interview with Koji Kita, Professor, Department of Advanced Materials Science

Semiconductor devices are pervasive, and various types of devices are categorized according to their structures and purposes. Power semiconductors (power devices) that can control enormous amounts of electric power are increasingly required in industries. Similar to logic semiconductors used in computers, Si, which is cost-effective and exhibits stable properties, is widely used in power devices.

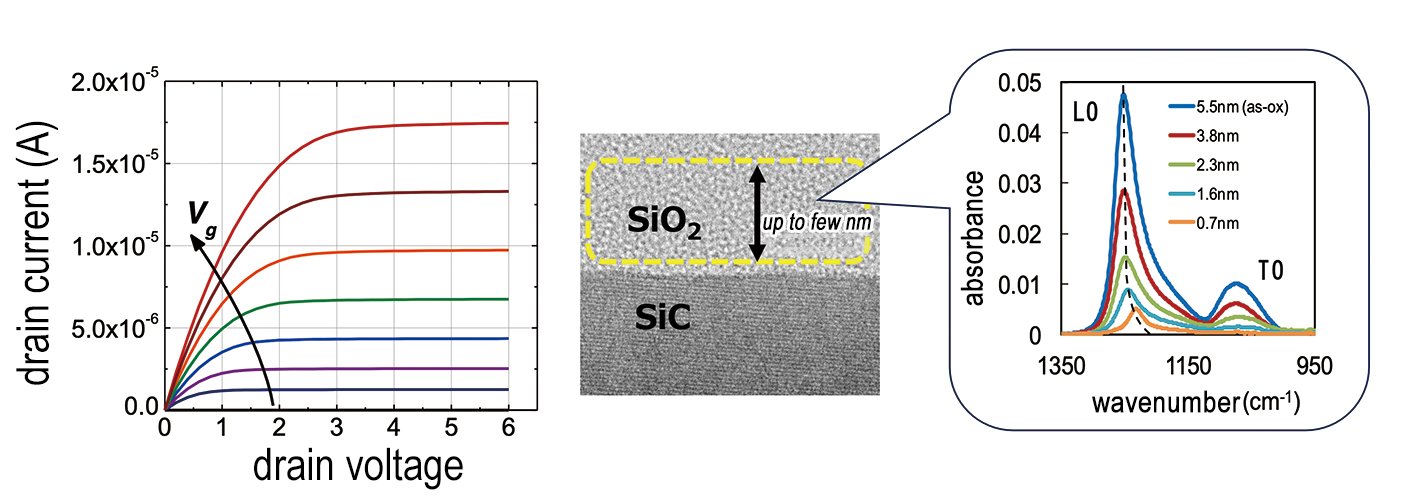

Silicon carbide (SiC) is expected to exhibit excellent properties and has been recently utilized in certain trains and cars. If highly superefficient power devices with SiC become widely available, energy loss during operations and power conversion will significantly reduce. However, Koji Kita notes the obstacles in achieving this goal.

“When fabricating transistors with SiC devices, impurity and distortions tend to appear on the interface at the nanoscale compared with the case of Si devices. It is not easy to have SiC exhibit its natural properties as is commonly assumed. SiC is only beginning to be used in cases when cost and property are balanced, and its full potential has yet to be exploited.”

A transistor, the core of a semiconductor device, functions by modulating the number of careers (movable electrons, i.e., conduction electrons and holes) in semiconductors in response to external voltage. It functions mainly in areas from a few nano to a few tens of nanometers to the interface of a semiconductor and an insulator. The properties of materials in this area control the properties of the device. Kita is currently attempting to elucidate the phenomenon that occurs in the nano-level neighborhood of the SiC power transistor interface and control the alignment and properties of atoms through the most effective process.

The government set the goals of power device production in the Next-Generation Digital Infrastructure Construction Project promoted by the New Energy and Industrial Technology Development Organization (NEDO) as follows:

-Reducing power loss in power devices using SiC or other materials by 50% or more by 2030

-Lowering the mass production cost to be as low as that of conventional Si power devices

-Developing power devices using gallium (Ga2O3), which is anticipated as the post-next-generation element

The approach of planning for the desirable future and working backward is becoming popular in semiconductor research in materials science. Kita’s laboratory has initiated basic research on Ga2O3 in addition to SiC.

(Left) Example of basic property evaluation of SiC transistor

(Center) Interface of semiconductor (SiC) and gate insulator (SiO2)

(Right) Structural analysis of infrared spectroscopy

5. The Goal of Modern Alchemy is Hyper-Super Heat-Resistant Material Design

Interview with Yoko Yamabe-Mitarai, Professor, and Sae Matsunaga, Assistant Professor, Department of Advanced Materials Science

Mitarai’s laboratory focuses on heat-resistant metal materials used in aircraft jet engines and gas turbines at thermal power plants. These metal materials were traditionally made by adding small amounts of other element(s) to iron, titanium, or nickel. However, since a new concept called “high-entropy alloy (HEA)” emerged approximately 20 years ago, scientists worldwide have begun to research alloys based on this concept.

HEA is defined as “a solid solution alloyed with five or more kinds of metals at high concentration.” It was coined to describe each element aligned in a crystal lattice at an almost equal atomic ratio, increasing entropy (high-entropy state).

“HEAs exhibit excellent properties, such as high strength, ductility, toughness, and thermal stability, due to lattice distortion and slow diffusion. Thus, they are promising materials for application in structure materials, catalysts, and magnetic materials. We are currently attempting to clarify the mechanical properties and deformation mechanism of HEAs, particularly in high-temperature environments, to create heat-resistant metals. However, if we strictly adhere to the HEA definition, it restricts us from generating innovative alloy designs. Thus, we are fabricating various trial alloys, free from the HEA definition but with flexible approaches to achieve diverse alloy compositions. We are experimenting with new combinations of elements and studying their properties and structures. We are currently repeating this experimental process,” says Mitarai.

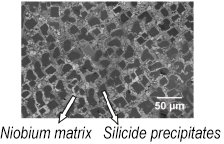

This iterative process led to Matsunaga’s experimental research paper “Phase stability and mechanical properties of Nb-silicide-based alloys with new elements added at high temperatures,” published this spring.

“Nb-silicide-based alloys have been attracting attention as next-generation heat-resistant materials for highly efficient aircraft engines and blades of gas turbines for power generation since the 1990s. Nevertheless, the alloying elements have always been the same, and only a handful of studies have defined elements effective for solving present problems. Thus, I added zirconium and other elements that are strong candidates in various patterns and investigated the phase stability at high temperatures and the effects on mechanical properties at room and high temperatures. The mechanical properties significantly improved at 1,300°C or higher by adding these elements. Moreover, Forming large silicide phases that have high silicon contents by microstructure control mainly contribute to strengthening the alloy,” explains Matsunaga.

This outcome has raised expectations for accelerating the development of Nb-silicide-based alloys that meet industrial requirements.

The new Nb-silicide-based alloy synthesized by Matsunaga

6. Project Management for Solving Social Problems by Materials Science

Interview with Kohzo Ito, University Professor

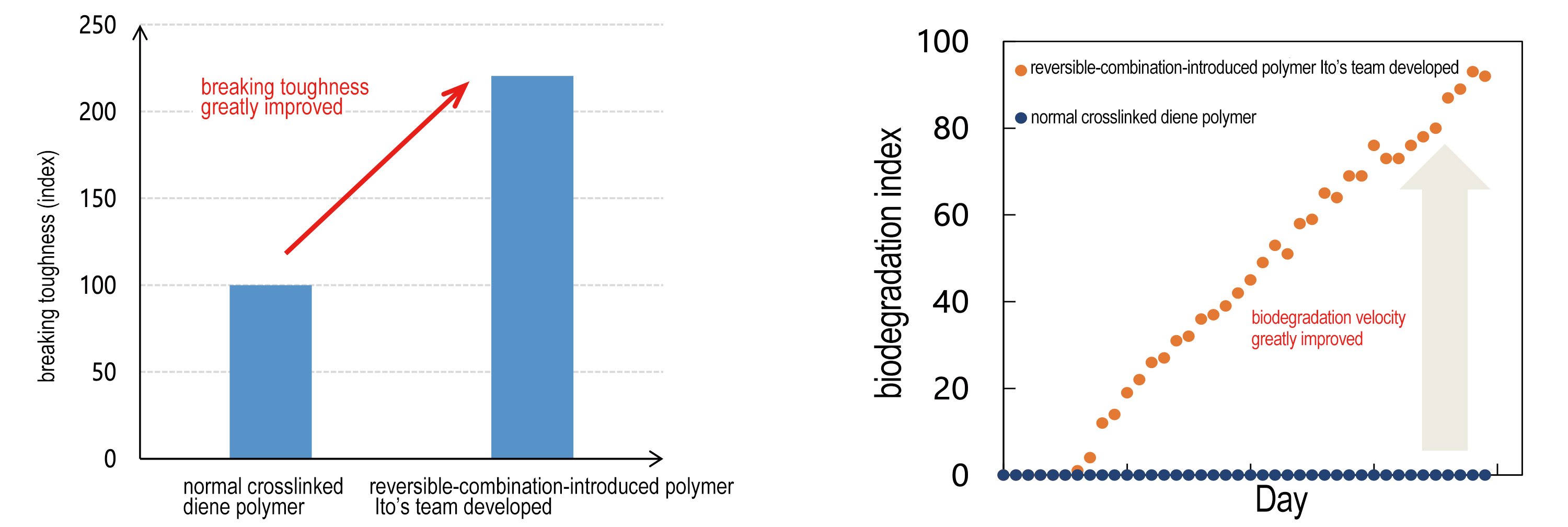

Kozo Ito has been researching the structures and properties of soft materials for many years. His major research outcome is the synthesis of a slide-ring gel whose crosslinking points freely move. He has expanded his scope of activity and is leading government’s large research projects. One of them is the “Development of Multilock Biopolymers Degradable in Ocean from Nonfood Biomasses” project by the Moonshot Research and Development program.*1

“There have been discussions on designing and synthesizing eco-friendly polymers for a long time. However, biodegradability and durability/toughness are in a trade-off relationship. To resolve this problem, this project aims to use a “multilock mechanism” to decompose polymers. Polymers simultaneously require multiple stimuli, including heat, oxygen, water, enzymes, microorganisms, and catalysts to decompose. Our method is to prevent deterioration due to degradation when in use and realize rapid decomposition after use, particularly when they are diffused in the ocean,” explains Ito.

“We will promote this joint research project with researchers from industry, academia, and governmental reseach institute, introduce a novel concept of polymer degradation and toughness invented in Japan, establish a design policy for multilock biopolymer materials, and promote practical applications by technology transfer to Japanese companies with mass production and cost reduction. If we can realize these goals, this process will significantly contribute to solving global environmental challenges,” emphasizes Ito.

Another large project he is supervising is the Cross-ministerial Strategic Innovation Promotion Program*2. Ito serves as the program director of the “Establishment of Circular Economy,” one of the 14 themes of the program. The goal is to promote a circular economy*3 by reviewing the methods of designing, producing, using, recycling, and discarding plastics.

“Realizing a circular economy is a social challenge that is as important as carbon neutrality. The Global Plastic Treaty to eradicate plastic pollution is expected to be approved by 2040. Novel polymer technologies are essential, and changes in the lifestyles of consumers and political actions are necessary to achieve a circular economy. Thus, experts in social psychology and environmental regulation participate in this project as subdirectors,” says Ito.

Materials science is a transdisciplinary academic field inherently. Material scientists will increasingly be appointed to lead large transdisciplinary research projects. Ito is one of those who demonstrate leadership in materials science research.

NOTES

- The Moonshot Research and Development Program is a government-sponsored project that commenced in 2020, following the Impulsing Paradigm Change through Disruptive Technologies Program, which was implemented from 2013 to 2018.

- It is a national project with the Council for Science, Technology, and Innovation in the Cabinet Office as the commander, aiming for scientific and technological innovations by management beyond the framework of ministries, agencies, and fields.

- Contrary to the conventional linear economy model with mass production, consumption, and disposal, the circular economy is an economic model of the long-term use of products and waste recycling.

A typical Achievement of the Moonshot Research and Development Project: Usual crosslinked rubber is not biodegradable, but the developed rubber with the reversible crosslinking technology shows more than twice the breaking toughness and 10 times the biodegradability.

After the Interviews

The 21st century is said to be “ a century of materials.” Materials science will significantly impact science, technology, industry, and even the entire society. Materials science research mainly conducted in the Department of Advanced Materials Science, GSFS, is rapidly progressing, expanding its focus from the basics to applications. Moreover, certain venture businesses have been launched at the projects.

In addition, human resource development for materials science is important. Thus, the Department of Advanced Materials Science offers opportunities for students to study physics, chemistry, and material engineering cross-sectionally from the basics. Additionally, students can apply to supporting programs, including the World-Leading Innovative Graduate Study Program for Materials Research, Information, and Technology (MERIT-WINGS) and World-Leading Innovative Graduate Study Program-Quantum Science and Technology Program (WINGS-QSTEP). This will highlight the real value of research and education in materials science at the GSFS.

Interview and text by Kazutada Furui

vol.44

- Cover

- The Potentials of Materials Science

- A Turning Point of Fusion Energy Research: Increasing Commercial Ventures for Practical Application

- Pioneering New Life Science with Parasitology and Bioinformatics

- For Acquisition and Proper Use of Water Environment Data

- GSFS Front Runners: Interview with an entrepreneur

- Voices from International Students

- On Campus/Off Campus

- Event & Topics

- Awards

- Information

- Relay Essay